Increased production capacity and improved product quality

Run and efficiently scale on a wide range of Intel CPUs

Computer vision is already transforming manufacturing processes, with numerous applications such as visual inspection, safety monitoring, defect detection, supply chain management, and more. Computer vision-based solutions deliver the intelligence to simplify processes, drive new efficiencies, and empower faster decision-making.

Applied Materials is a leader of materials engineering solutions that produce the chips that power everything from smartphones and laptops to medical equipment and household appliances. As a leader in their space, Applied Materials uses cutting edge computer vision technology to solve the biggest challenges in chip manufacturing and meet the growing demands from the semiconductor industry.

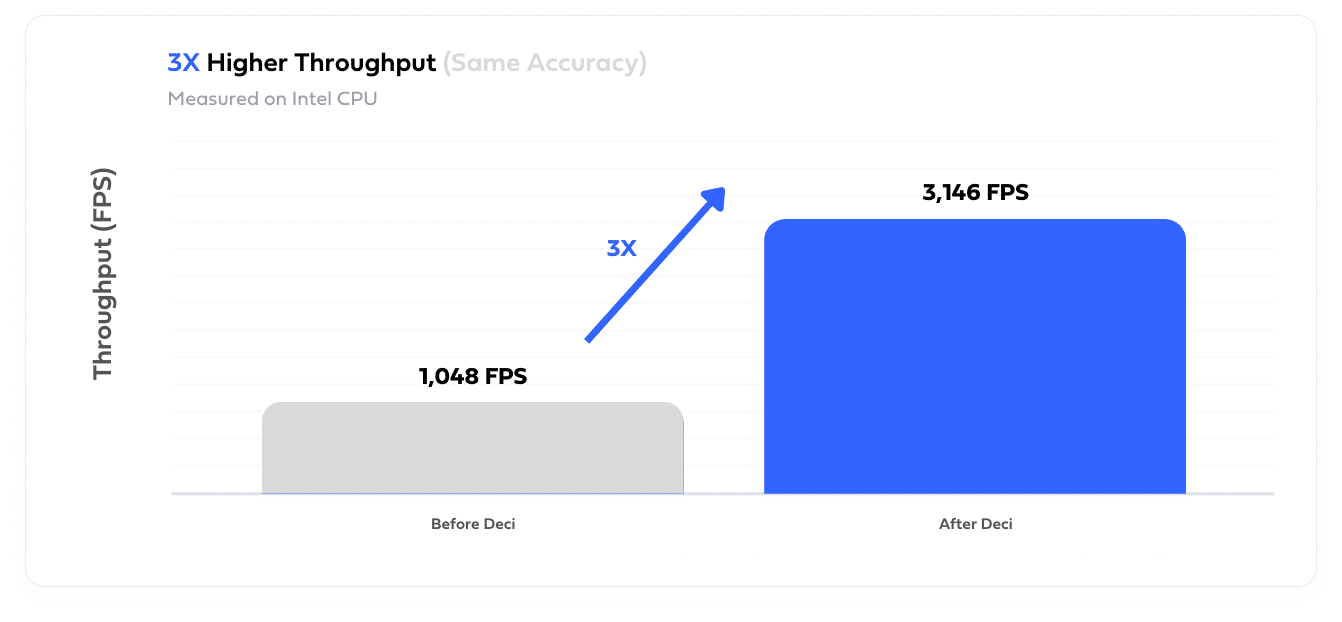

Applied Materials has been leveraging the power of computer vision for visual inspection to improve production line capacity, minimize errors, and ensure high product quality. Being at the forefront of AI innovation, they were looking to enhance processes further and bring repeatability, consistency, and better decision-making. To do this, Applied Materials sought to significantly improve the performance of a critical image classification model by achieving a higher throughput on Intel CPUs while maintaining accuracy.

The team at Applied Materials used the Deci platform and AutoNAC, Deci’s proprietary Neural Architecture Search engine, to build a custom image classification model with better hardware utilization to meet their requirements and performance targets. After Applied Materials trained the new AutoNAC-generated model in their secured internal environment, it not only maintained the baseline accuracy but also offered increased throughput, helping to significantly improve the whole solution’s efficiency

With the performance improvement that Applied Materials achieved using Deci, they enhanced visual inspection processes, increased production capacity.

Increased production capacity and improved product quality

Run and efficiently scale on a wide range of Intel CPUs

Improve latency and throughput, and reduce model size by up to 5X while maintaining the model’s accuracy.

Maximize hardware utilization and cost-efficiently scale your solution at the edge.

Simplify development with automated tools that guarantee success.

Choose an ultra performant model or generate a custom one.

AutoNAC

Neural Architecture Search Engine

DataGradients™

Dataset Analyzer

Use Deci’s library & custom recipe to train on-prem.

SuperGradients™

PyTorch Training Library

Apply acceleration techniques. Run self-hosted inference anywhere.

Infery

Optimization & Inference Engine SDK

Tell us about your use case, needs, goals, and the obstacles in your way. We’ll show you how you can use the Deci platform to overcome them.

Deci is ISO 27001

Certified

from transformers import AutoFeatureExtractor, AutoModelForImageClassification

extractor = AutoFeatureExtractor.from_pretrained("microsoft/resnet-50")

model = AutoModelForImageClassification.from_pretrained("microsoft/resnet-50")