Computer vision-based solutions deliver the intelligence to simplify processes, drive new efficiencies, and empower faster decision-making. However, the inability to run real-time inference, high false alarms due to low model accuracy, and the failure to deploy on CPUs or edge devices are just some of the barriers to production faced by AI teams in manufacturing companies today.

Watch a compilation of clips demonstrating how you can use Deci in a variety of manufacturing use cases.

A manufacturing company specializing in materials engineering for the semiconductor industry sought to improve their defect detection inspection process and capacity by accelerating their model’s runtime performance.

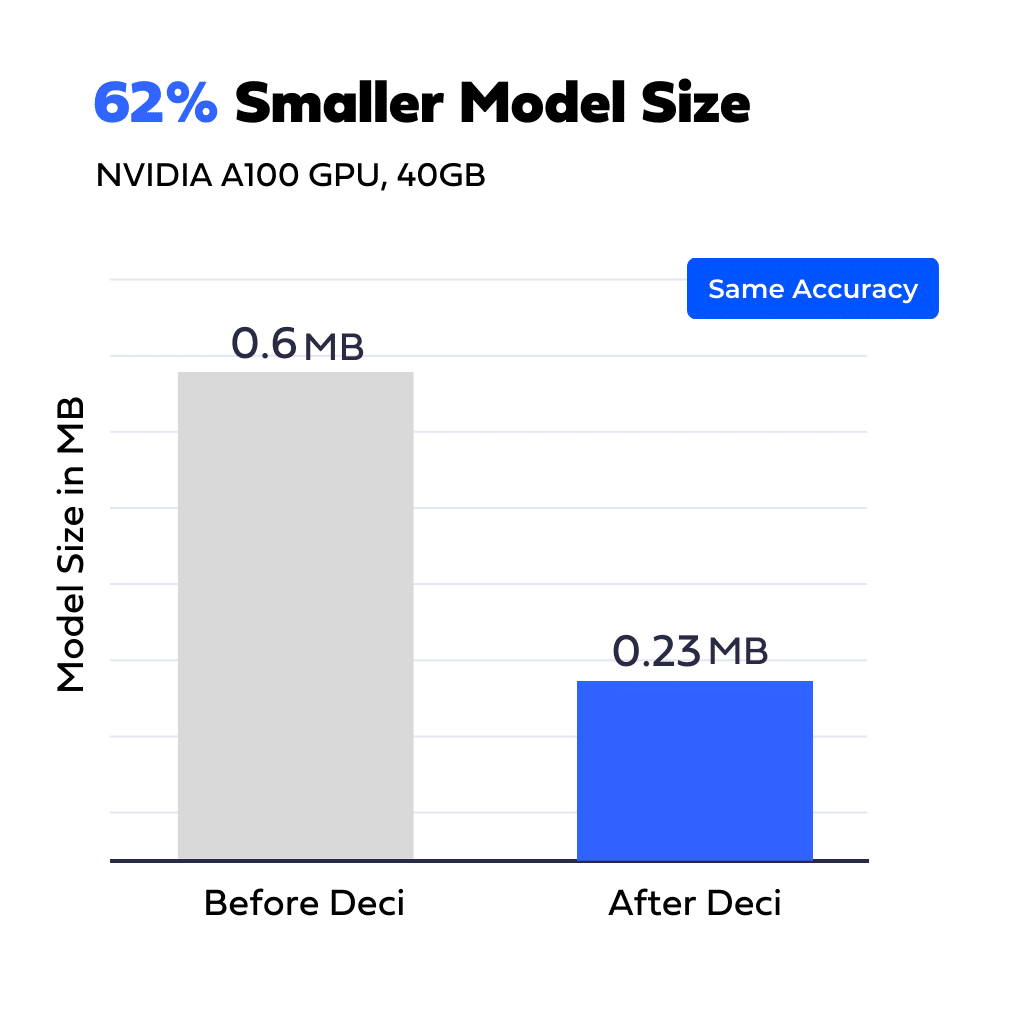

The team used the Deci platform and its NAS engine to build a custom segmentation model that delivered a 1.6x increased throughput, a 62% reduction in model size, and a 13% reduction in memory footprint while maintaining the accuracy. The new model was trained on-premise using Deci’s open-source training library called SuperGradients and then compiled and quantized the model to TensorRT FP16 using Deci’s platform.

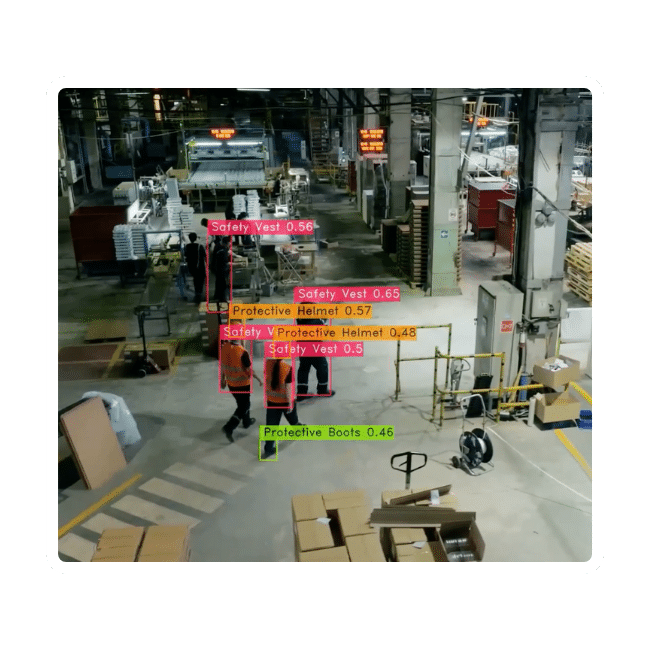

A company enabling manufacturers to digitally transform operations with a connected, IoT-native, no-code platform sought to enhance its safety personal protective equipment (PPE) identification offering by improving the model’s accuracy and latency on CPUs and other resource-constrained edge devices.

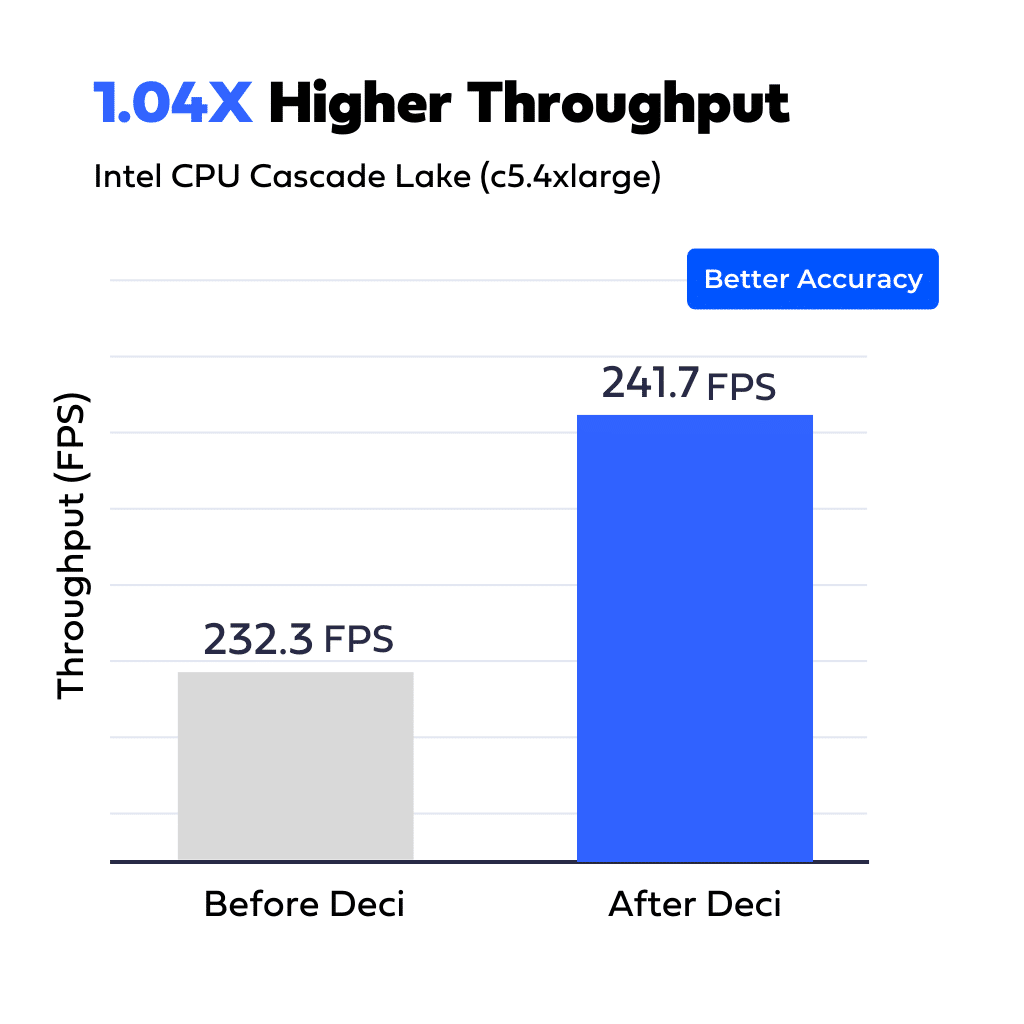

The team used the Deci platform and its NAS engine to develop a custom object detection model that delivered a 14.7% increase in accuracy and a 1.04x boost in throughput. The company deployed the model on a wide range of hardware environments and enhanced its safety PPE identification solution.

Amir Bar, Head of SW and Algorithm

Applied Materials

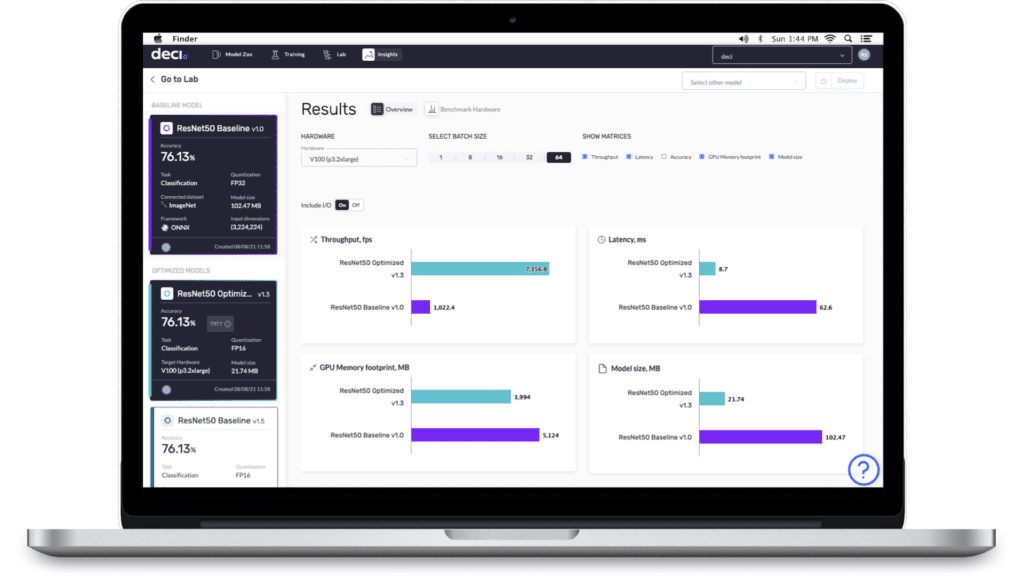

The Deci platform is used by data scientists and machine learning engineers to build, optimize, and deploy highly accurate and efficient models to production. Teams can easily develop production grade models and gain unparalleled accuracy and speed tailored for any performance targets and hardware environment. Deci is powered by AutoNAC (Automated Neural Architecture Construction), the most advanced and commercially scalable Neural Architecture Search engine in the market. AutoNAC performs a multi-constraints search to find the architecture that delivers the highest accuracy for any performance targets and hardware environment.

Build accurate & efficient architectures tailored to your hardware and application’s performance targets with Deci’s Neural Architecture Search engine.

Easily compile and quantize your models (FP16/INT8) and evaluate different production settings with a click of a button.

Train models with SuperGradients. Leverage custom recipes and advanced training techniques (e.g. knowledge distillation, quantization-aware training) with one line of code.

Deploy your models with Infery, Deci’s simple-to-use, unified, model inference API. Streamline deployment and boost serving performance with parallelism and concurrent execution. Compatible with multiple frameworks and hardware.

Deci is ISO 27001

Certified

from transformers import AutoFeatureExtractor, AutoModelForImageClassification

extractor = AutoFeatureExtractor.from_pretrained("microsoft/resnet-50")

model = AutoModelForImageClassification.from_pretrained("microsoft/resnet-50")